What is butter paper used for?

Our Products

Why Choose Ekvee?

Greaseproof

Moisture Balancing

Food Grade Ink

Biodegradable

Non-stick Surface

Latest Blog Posts

In a rapid-paced commercial kitchen or a large-scale bakery, each tool must improve efficiency, be optimised, and be contamination-free. Among mixers, ovens, and moulds, one simple yet high-performance material seamlessly supports the daily process—baking paper. Often underappreciated, baking paper has become a backbone for commercial kitchens that value speed, hygiene, and reliable results.

From artisan bakeries to industrial food production units, baking paper supports chefs' emphasis on creativity while securing efficiency. Let’s examine the top uses of baking paper/parchment paper in commercial kitchens and bakeries—and why it’s a mandatory essential.

1. Non-Stick Baking for High-Volume Production

One of the reasons why baking paper is so highly appreciated is its ability to resist sticking well. When trays go into the oven by the hundred, any degree of sticking could lead to lost product or delays.

Baking Paper helps in the easy removal of:

- Cookies and brownies

- Bread loaves and buns

- Cakes and sponge bases

This uniformity is crucial for retaining the identical form, texture, and finish—the essence of commercial display and consumer satisfaction.

2. Faster Turnaround & Improved Kitchen Efficiency

Speed is paramount in a commercial kitchen. Parchment baking paper removes the requirement to grease trays or moulds, saving a tremendous amount of time in preparation. Once baking is complete, trays can be cleared, wiped, and reused almost immediately.

This means:

- Faster batch cycles

- Reduced labour effort

- Smoother workflow during peak hours

There is baking paper that can bear high temperatures and continuous usage for bakeries with consecutive production schedules, ensuring continuous, uninterrupted operations without quality loss.

3. Cleaner Equipment, Lower Maintenance

Grease accumulation and burning residue are common issues in busy kitchens. Baking papers work as an active barrier between the food and the trays to prevent the accumulation of oils, sugar syrup, and fillings.

This results in:

- Wash and soak less

- Increased lifespan of baking trays and moulds

- Enhanced standards of hygiene and kitchen efficiency

A cleaner kitchen saves time as well as helps with food safety regulations, which is a crucial element for food-related businesses.

4. Heat Stability for Consistent Baking Results

There is a need for accuracy in commercial baking. Baking paper is made to handle high temperatures from the oven. At the same time, it ensures adequate distribution of heat along the surface of the food.

This assists in achieving:

- Controlled moisture retention

- Uniform texture in the product

Whether it is making macaron cookies or making bread, baking paper ensures consistency in performance.

5. Versatility Beyond the Oven

Far from being just a simple baking aid, baking paper is extremely versatile, turning this product into a multi-functional workhorse within the commercial kitchen.

Other common alternative uses include:

- Lining of work tables for dough preparation

- Wrapping of butter, chocolate, or confectionery items

- Separating tiered bakery items

- Making a dough roll and shaping it without additional flour

This versatility decreases dependency on several materials and simplifies kitchen inventory.

6. Ideal for Large-Scale Baking & Batch Control

In large bakeries, baking paper makes items more standardised and consistent in size and portion. The pre-cut baking sheet makes it easier to cover a tray uniformly, hence increasing portion control and consistency

This is particularly helpful when dealing with:

- Industrial baker

- Cloud kitchens

- Catering

- Food production centres

Standardised baking surfaces create consistency between brands, which is recognisable to consumers from the moment they see it.

7. Supports Grease Management & Food Presentation

For products containing high amounts of butter, oil, or cheese, baking paper absorbs the excess grease without affecting the texture. This leaves the final product clean with improved appearance.

In bakeries where presentation matters, this small detail ends up making a very big impact, especially when it comes to products such as pastries, croissants, and savoury bakes.

8. Sustainable & Responsible Choice When Sourced Right

Sustainability is increasingly becoming the focus of concern for many, with the result that many commercial kitchens are turning to responsibly sourced baking paper. Quality baking paper prevents waste by limiting the amount of rejected products, detergents, or excessive use of oil.

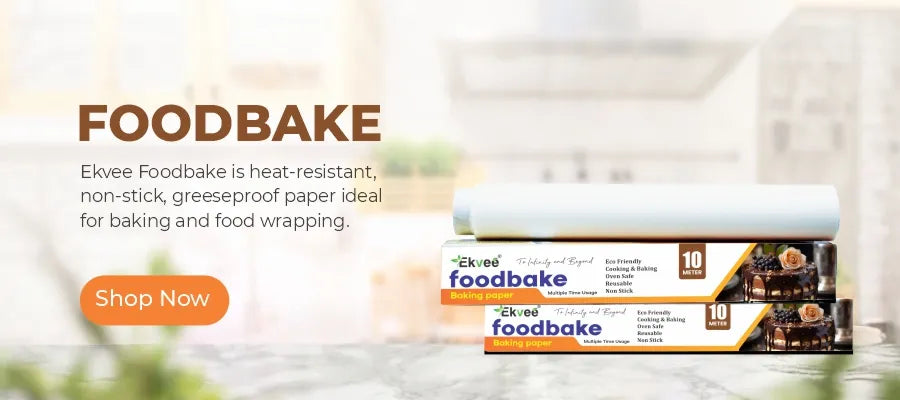

Being packaged from a reliable supplier such as EKVEE, foodbake baking paper roll can be an effective aid in terms of operational efficiency as well as an environmentally friendly practice.

Why Baking Paper Is a Must-Have for Modern Kitchens

Commercial kitchens, as well as bakeries, know success is made through consistency, velocity, and the right allocation of resources. Baking paper does all three, quietly, every day.

This helps streamline processes, safeguard machines from damage, enhance the quality of food products, and maintain high hygiene standards. Whether it’s a small bakery or an industrial baking setting, baking paper is more than just a helpful resource; it is essential.

We at EKVEE know the true requirements of a commercial kitchen. Our baking paper is designed to perform in these conditions, to perform where it counts.

Because in commercial bread-making, the smallest detail is the most significant.

In today’s high-velocity food industry, packaging is no longer just about wrapping a product—it’s about preserving quality, improving visual appeal, and providing a better customer experience. As consumer requirements rise and food brands stand out in the market, one packaging material has gradually become fundamental: greaseproof paper.

From street food counters to high-quality bakery brands, greaseproof paper is transforming how food is packed, served, and regarded. Its adaptability, functionality, and sustainability factors make it a true game-changer for advanced packaging solutions.

The Growing Demand for Smarter Food Packaging

The food industry has developed rapidly. Fast-delivery restaurants, cloud kitchens, bakeries, and takeaway brands now manage in an environment where speed, hygiene, and eco-smart design are mandatory. Customers want food that reaches their hands fresh, visually appealing, and feels safe to consume.

This is where greaseproof paper plays an essential role. Designed to endure oil and moisture, it guarantees that food stays intact, packaging remains clean, and the overall presentation continues to be appealing—no soggy wraps or greasy stains.

What Makes Greaseproof Paper So Effective?

Greaseproof paper is manufactured with a compact fibre structure that prevents oil and fats from leaking. Unlike ordinary paper, it preserves its strength even when exposed to greasy or moist foods.

Its main benefit lies in its capability to handle an extensive selection of food items—hot, cold, oily, or baked—without sacrificing quality. Whether it’s wrapping a crispy croissant or coating a box of fries, greaseproof paper operates steadily.

Enhancing Food Presentation and Brand Value

First impressions matter, particularly in the age of social media. Food that appears neat and well-packaged immediately feels more luxurious. Greaseproof paper helps preserve that visual appeal by keeping packaging clean and organised.

For brands, this converts into a stronger brand opinion. Custom-printed greaseproof paper can also be used as an understated branding tool, transforming simple wraps into brand ambassadors. Every takeaway order becomes a prospect to strengthen identity and professionalism.

A Versatile Solution Across Food Segments

One of the biggest advantages of greaseproof paper is its flexibility across multiple food categories:

- Bakeries & Cafés: Ideal for wrapping pastries, cakes, cookies, and breads without affecting texture or freshness.

- Quick-Service Restaurants: Perfect for burgers, wraps, sandwiches, and fries, where oil control is essential.

- Street Food & Takeaways: Helps maintain hygiene while offering convenience and durability.

- Food Delivery & Cloud Kitchens: Ensures food reaches customers in a clean, presentable condition despite longer delivery times.

This adaptability makes greaseproof paper a standard in both authentic and contemporary food operations.

Supporting Sustainability Goals

Sustainability is no longer a trend—it’s an objective. Consumers are gradually becoming conscious of the environmental impact of packaging materials. Greaseproof paper, particularly when produced responsibly, offers a more long-lasting alternative to plastic-based food wraps.

Paper-based solutions are simpler to recycle and align well with worldwide initiatives to minimise single-use plastics. By selecting high-quality greaseproof paper, food brands can take a significant step toward eco-conscious packaging without reducing performance.

Hygiene and Food Safety at the Core

Food safety can play a critical role in the handling of foods at all stages. Greaseproof paper provides a protective covering over the food as well as from outside contaminants.

Its food-safe qualities are an added advantage as it can be in direct contact with food and provides consumers with an added safe and hygienic attribute when choosing their food products. In today’s world, cleanliness and safety are key factors influencing the purchasing aspect.

Cost-Effective Without Cutting Corners

Greaseproof papers, despite having high-performance characteristics, are still an inexpensive packing solution for businesses. Greaseproof papers have strength properties that eliminate the need for double wrapping or the use of inner liners.

Further, it is easy to use. This ensures that operations are more efficient because employees can pack as well as serve meals faster. This is particularly crucial, especially when dealing with large volumes.

Why Greaseproof Paper Is the Future of Food Packaging

With innovations rising in the food industry, packaging materials should not be left behind. Greaseproof paper is exceptional because it combines functionality, beauty, environmental factors, and cost-effectiveness.

For contemporary food brands, this is no longer an alternative option, but has instead become essential. "Whether it's better food presentation, better hygiene, or going greener, grease-proof paper meets all these criteria."

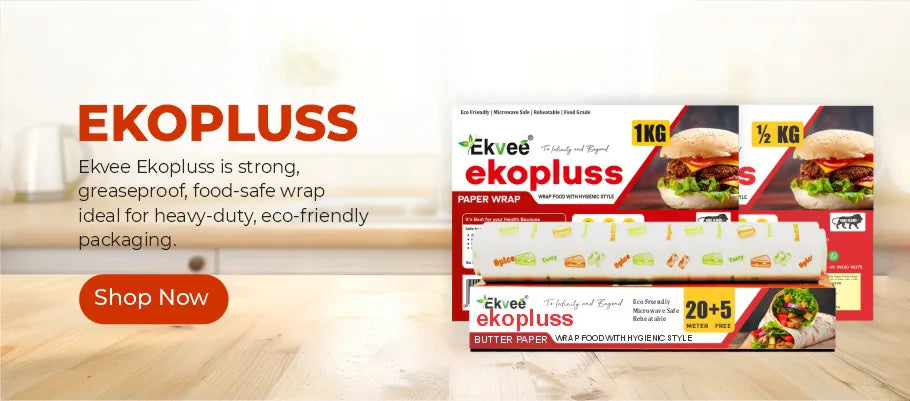

EKVEE: Powering Smart Packaging Solutions

At EKVEE, we are well aware of the dynamic needs associated with the food sector. Our premium greaseproof paper line has been designed to take care of the current requirements associated with modern packaging.

In a world where the voice of the package speaks just as loudly as the product, greaseproof paper shows that intelligent decisions lead to lasting impacts. For any food business that wants to stay one step ahead, it simply has to be a requirement.

Food safety is something that you cannot compromise on, especially when it comes to handling, wrapping, baking, or packaging food items. Considering the shifting lives, booming food delivery culture, and growing hygiene awareness, the demand for the use of food-grade packaging materials is greater now than ever before. One of those commodities that play an essential role in food packaging is Food Grade Butter Paper. But really, what truly makes it safe for food? What standards should it meet? And how does one assure oneself that he is choosing the right one?

What is Food-Grade Butter Paper?

Food grade butter paper is specially designed to safely come in direct contact with food without causing contamination. It is primarily used for wrapping and protecting food items, maintaining hygiene, and preventing grease transfer. Unlike baking paper or parchment paper, butter paper is not meant for baking or high-heat cooking; it is only a wrapping paper meant for food safety and packaging. Food-grade butter paper is coated with food-grade, non-toxic materials, such as silicone.

Unlike normal paper, food-grade quality papers, or food grade quality butter paper, is manufactured under quality control and hygienic conditions so that they will not transfer harmful substances, chemicals, or ink to the food.

Why Safety Standards Matter?

Food packaging is not just a matter of wrapping food; it is about protecting health, freshness, and quality. The use of unsafe or poor-quality paper may:

- Transfer of chemicals to food

- Affect taste, smell, and texture

- Spoil food

- Lead to health risks and infections

- Damage brand trust and reputation

This is why compliance and certification become highly important. Ekvee makes sure that its butter paper adheres to recognized national and international standards so that every sheet assures safety, purity, and peace of mind.

International & National Safety Standards for Food-Grade Butter Paper

To be considered truly “food grade,” butter paper needs to meet certain strict regulatory norms. These include:

1. FDA (Food and Drug Administration) Compliance

The FDA ensures the following about the packaging materials used in food

- Safe for direct contact

- Free from harmful migration chemicals

Ekvee’s butter paper will retain quality and safety standards, whether it is being used for cooking or wrapping hot food.

2. European Union Regulations

For instance, the EC No. 1935/2004 standard and the EC No. 2023/2006 standard set the guidelines for the manufacturing or testing of food contact materials. These

- Chemical transfer is

- Safe at various temperatures

3. FSSAI and BIS Compliance in India

In India, food packaging should conform to:

- FSSAI

- BIS Standards

These are to make sure that the butter paper is appropriate for use in Indian kitchens as well as in food-related businesses.

4. ISO Quality Management Standards

Premium butter paper can be described as having the following characteristics:

- ISO 22000 - Food Safety Management

- ISO 9001 – Quality Management System

These ensure regulated manufacturing, cleanliness, and authenticity.

What Makes Ekvee Food-Grade Butter Paper Truly Safe?

Not all sheets of butter paper are food grade. Truly, food grade butter paper should have certain properties, all of which Ekvee provides:

- Non-stick surface, which helps prevent food from sticking

- Grease & Oil Resistant - Keeps food fresh and clean

- Heat Resistant – For baking and hot wrapping

- Chemical-Free Composition – No harmful leaching

- Odourless & Tasteless – Does Not Affect Food Flavors

- Moisture Protection - Extends food texture shelf life

-

Smooth & Durable Quality – Preventing Tearing

Each Ekvee butter paper is made with care to ensure the food in it remains safe, clean, and fresh.

Temperature Tolerance & Safe Usage

Quality speaks for itself. Food-grade, superior butter paper like Ekvee’s can resist up to 220°C – 250°C, thus being perfect for:

- Baking of cakes, cookies & biscuits

- Chapati, roll, burger, and sandwich wrapping

- Lining of baking trays & steaming containers

- Food takeaway and delivery packaging

Nevertheless, it should not be confused with plastic-coated paper, newspapers, brown packing sheets, or ordinary writing paper, which are unsafe for food.

Where is Food-Grade Butter Paper Used?

Food-grade butter paper has immense uses in various industries:

- Bakeries & Pastry Shops - For baking and wrapping

- Restaurants & Cafés – For serving, storage & takeaway

- Food Delivery Brands - For Safe and Professional Packaging

-

Hotels & Catering Services – For mass handling and storage

Ekvee Butter Paper is always a smart, safe, and reliable option for food handling.

Benefits of Using Certified Food-Grade Butter Paper

Using certified food-safe butter paper has several benefits:

- Guarantees absolute food safety

- Conserves freshness & taste

- Prevents contamination

- Enhances presentation and hygiene

- Meets legal compliance

- Establishes brand credibility

- Boosts customer loyalty

In simple language, it can be said to safeguard one’s health and reputation.

How to Identify Genuine Food-Grade Butter Paper?

Due to growing requirements, copying and inferior examples become available in the market. For ascertaining original butter paper, one must verify these aspects:

- Food-Grade

- FDA / FSSAI / BIS Labels

- Authentication of

- Silicone coating non

- No chemical odor

- Strong durability & thickness

With Ekvee, you don’t have to worry. The company is dedicated to offering the best, safest, and certified butter paper.

Environment-Friendly Choice

Along with safety, Ekvee believes in sustainability. Most quality food-grade butter papers are:

- Eco-friendly

- Biodegradable

- Compostable

They are a healthier alternative to plastic wraps and contribute to environmental protection.

Final Words – Choose Smart. Choose Safe. Choose Ekvee.

This food-grade butter paper is not just a packaging material but a protective shield for your food and health. Compliance with international and national standards assures safety, hygiene, and trust.

Due to this fact, Ekvee's premium Food-Grade Butter Paper provides assured quality, certified safety, high performance, and peace of mind. Whether home cook, bakery owner, restaurant professional, or food entrepreneur, always opt for trusted, certified, and branded butter paper, because when it comes to food, safety always comes first.

Wrap your food with care, bake it with perfection, and deliver it with hygiene. Ekvee Food Grade Butter Paper is an ideal partner!

What Our Customers Think!

Frequently Asked Questions

We're Available on